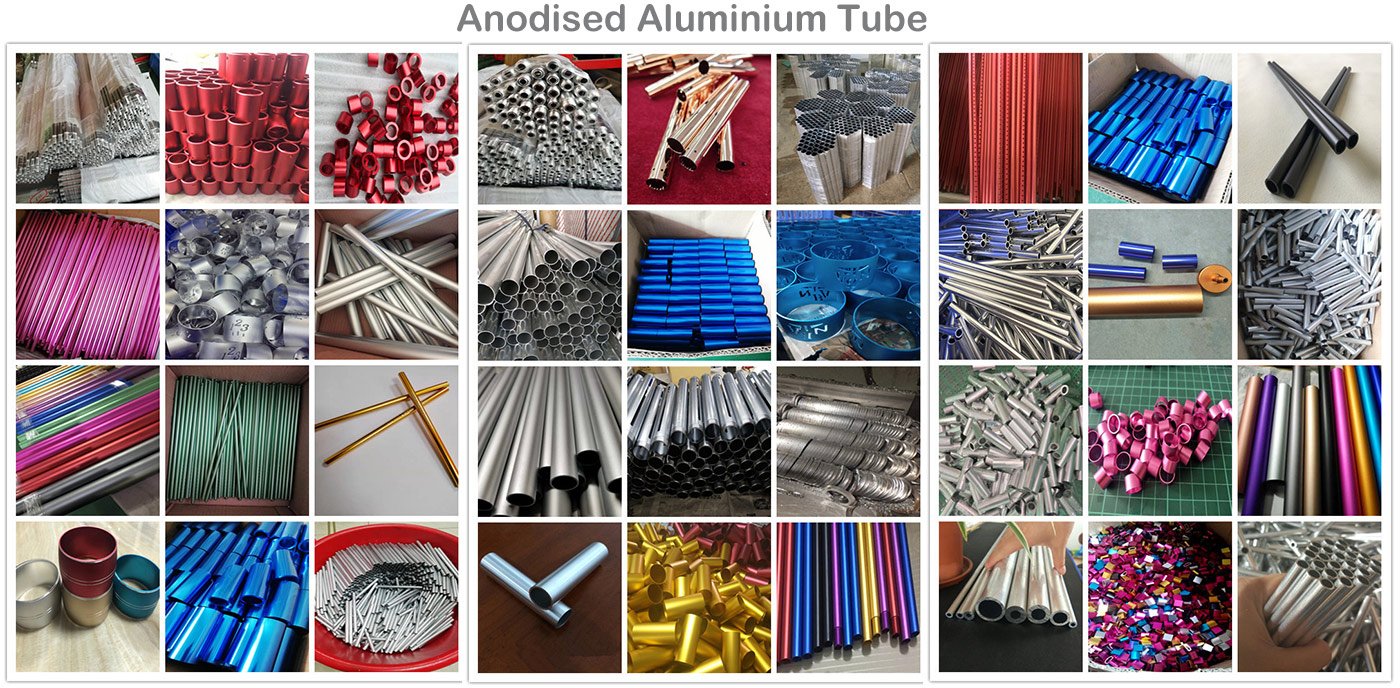

- Various engrave patterns & Colors

- Lasting more than 20 years appearance

- Anodized protection film thickness from 6μm to 25μm

- Sliver, Bronze, Gold, Blue, Champagne, others upon on your request

Anodised Aluminium Tube

Wellste manufactures anodized aluminum tube which are widely used for fabrication project types. It is because our anodised aluminum tubes are corrosion resistant and lightweight.

Wellste anodized aluminum tube is available in both 6063-T6 and 6061-T6, other special alloy upon on your request, as like 5083 marine aluminum tubes, But if you are looking to have a brighter finish, we have 6063 which are more bendable.

Your Premier Anodised Aluminium Tube Manufacturer

Wellste has a huge number of different types of anodized aluminum tube. It comes with various colors and length.

It is available in bronze, dark bronze, nickel, brass and many others. However, we have a standard polished aluminum tubing that you might choose.

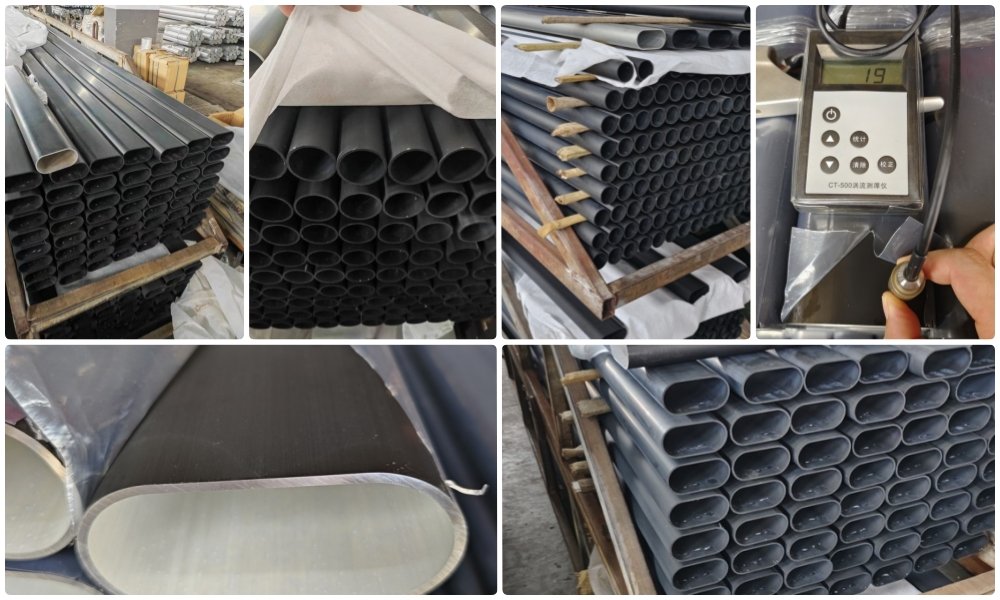

Wellste also manufactures a black aluminum tube which has a thick film with 20. Thus, it resists oxide film from the surface. It can allow direct current, high amperage, and low voltage into a profile solution. This black aluminum tube contains a surface which is passable from the oxidation layer. Perfect for applying dyes.

This Wellste black aluminum tube is able to absorb the dyes. The color will not fade when the dye is embedded. Also, it’s not even peeling when rain, snow, and direct sunlight exposure.

Our professional engineers designing black aluminum pipe that allows high conductivity and provides extremely resistant to corrosion. We offer a huge range of anodized aluminum tube which sustains deep processing such as welding, drilling, punching, and so on.

| Aluminum Grade | 6063, 6061, 6005, 6082 etc |

| Heat Treatment | T5 T6 T4 |

| Color | silver, black, champagne, bronze, golden etc |

| Surface | clear, sandy, brushed and polished |

| Application | home furniture, building material,industrial products etc |

| Production Time | 10-15 days mold time, 15-20 days bulk production time |

| Length | Long bar or cut to specific length |

| Packaging | wrap with film, load in pallet |

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Wellste air cylinder tubing is good for your hydraulic system application and so on. We stock a large number of air cylinder tubings in the warehouse and have no MOQ requirement for further cooperation. Feel free to get a full catalog from the sales team.

Wellste has more than one hundred existing sizes for the extruded aluminum tube. We accept sample prototyping and have very low MOQ to support your business in the developing stage. Wellste offers a one-stop solution for your project and quotes suitable prices.

Wellste threaded aluminum tube works actively in marine and transportation areas. Wellste aluminum tube has high-quality anodizing surface treatment and is able to resist any corrosion, especially when they work under water. It can transport fluid or gas without leaking.

Wellste 5086 aluminum pipe is widely used in the marine industry. Grade 5086 have excellent corrision resistance. It can also work well even under salty seawater. Its density is 0.096 lb/in3, so it is strong enough for your project. Our engineers will prepare a quick quotation.

Wellste seamless aluminum tube is in compliance with ISO 9001 standards. We focus on seamless aluminum tube production strictly. It doesn’t have any welding joint as an extruded aluminum tube. It won’t have any problem when transporting gas or oil. So it is very safe.

Wellste 7075 aluminum tube is popular in the aerospace industry. 7075 aluminum tube has strong strength and can withstand high load. It usually works as aircraft gears, fuses, and so on. Wellste offers high precision and support test reports after completing the production.

Wellste aluminum round tube covers a wide range of aluminum alloys, the most popular ones are 6000 series grades like 6063 and 6061. Wellste has hundreds of existing molds and can save extra mold fees for your project. We also offer CNC machining services if you have any extra requirements.

Wellste aluminum heatsink helps your devices to dispatch heat immediately. What’s more, we offer anodizing surface treatment for you. Anodized film thickness can protect the heat sink’s surface and give the heat sink a beautiful anti-corrision outlook. It is easy to clean with a smooth surface.

Wellste aluminum square tubing is good for your construction or any other structural project. The aluminum square tube is easy to weld and machinable. We have both sharp corners and corners with radius. It’s all up to your choice. We support an economical machining method for you.

Wellste: Your Leading Anodised Aluminium Tube Manufacturer

Wellste black aluminum pipe is clear, Brite dipped, satin, light champagne, and so on.

Wellste has a lot to offer anodized extruded aluminum tubes for construction such as windows, doors, screen, fence, curtain wall, partition, handrail, wardrobe, sunroom, and so on. Our qualified engineering team and professionals verified its authenticity.

They design and create anodized aluminum tubes with high quality. The strength is at a higher level capable to protect from harsh environment.

Wellste anodized aluminum tube provides an option and will enable you to custom your projects perfectly.

We offer brushed aluminum tube, black anodized tubes, and polished aluminum tubing with standard finishes to find you exact aluminum tube you need. The sizes of the product vary from your requirements and ideal application.

Wellste with good reputation always providing high-quality products, lower price, solid strength for our customers.

As a professional supplier and manufacturer of aluminum extrusion, Wellste engaged in domestic trading as well as international trading for 20 years. Our products are exported to many countries including the USA, Spain, Africa, Mexico, Italy, and Poland.

Moreover, Wellste inherits the advanced concept of industrial. We dedicate to the production of precision parts and metal casting with non-ferrous.

We own 35 advanced extrusion presses. We finished all the procedure processing from mold production to blank follows up the surface treatment production precision. We provide a one-stop service for you. If you choose Wellste, you can save a cost from purchasing and product development.

You are always welcome to contact us for business cooperation and technical inquiry. We are open 24/7 for quick response.

Anodized Aluminum Tube:

I know you’re looking for vital information about anodized aluminum tube.

A reason this guide will answer all your questions on anodised aluminum tube.

So keep reading to learn more.

- What Is An Anodized Aluminum Tube?

- Can You Use Anodized Aluminum Tube Outdoors?

- How Long Will Anodized Aluminum Tube Last?

- What Are The Types Of Anodizing You Can Use To Make Anodised Aluminum Tubes?

- What Are The Advantages Of Anodized Aluminum Tubes?

- Are There Disadvantages Of Using Anodized Aluminum Tubes?

- How Do You Anodize Aluminum Tubing?

- What Color Options Are Available For Anodized Aluminum Tubes?

- What Are Some Design Tips For Anodized Aluminum Tubing?

- What Are The Applications Of Anodized Aluminum Tubes?

- How Do You Check Quality Of Anodized Aluminum Tube?

- How Much Does Anodizing Aluminum Tubes Cost?

- Why Do Anodised Aluminum Tubes Have A Metallic Sheen To Them?

- Can You Refurbish Anodized Aluminum Tubing?

- How Do Anodised Aluminum Tubes And Non-Anodized Aluminum Tubes Compare?

- What Shapes Can Anodized Aluminum Tubes Come In?

- Are There Necessary Precautions To Consider When Anodizing Aluminum Tube?

What Is An Anodized Aluminum Tube?

This is an aluminum tube that comes with an anodized surface finish which passivates the aluminum alloy preventing it from oxidation.

Anodized Aluminum Tube

The anodization will form a chemically stable and protective surface finish making it corrosion resistant and abrasion-resistant.

Anodizing aluminum tubing entails using an electrochemical process to alter the surface into durable and resistant layers.

Can You Use Anodized Aluminum Tube Outdoors?

Yes, you can use it outdoors and it will remain in good condition.

The anodized surface finish protects it from various elements hence increasing its lifespan.

This feature makes it useful when constructing structures that will be exposed to atmospheric corrosion in the environment such as buildings.

A Camping Chair With An Anodized Aluminum Frame

How Long Will Anodized Aluminum Tube Last?

When you anodize the surface of aluminum tubes, you will minimize atmospheric corrosion which increases its lifespan.

Anodised aluminum tubes can last for between 10 years and 20 years, but this depends on the quality and thickness of the anodization.

What Are The Types Of Anodizing You Can Use To Make Anodised Aluminum Tubes?

The most popular variations of anodizing that you can apply when making anodized aluminum tubing are Type II and Type III.

Type II is also known as regular anodizing while Type III is also known as hard anodizing.

Besides, there is also Type I of anodizing.

Here are the anodizing types you can use to make anodized aluminum tubes:

Type I Anodizing

The two flavors of anodizing you can conduct here entail using chromic acid and boric-sulfuric acid.

Chromic Acid

This type of acid was used in the past but is becoming less common since it comes with some safety concerns.

The safety concern was related to air pollution that newer acids did not produce.

Besides, this is the oldest anodizing process which forms a soft anodized layer that is thin than hard or regular anodized finishes.

The thinness of this anodized surface ranges between 20 microinches to 100 microinches.

When you seal it properly, it will offer suitable protective characteristics despite being thin.

Also, you can use it for color anodizing as it offers grey color and will not absorb a lot of color during the drying phase.

Besides, you will not use this type for decorative purposes as the aluminum tube is black and lacks reflective traits.

Boric-sulfuric Acid

This is s subtype that you can use instead of chromic acid anodizing as it does not pose any environmental issues.

Boric-sulfuric anodizing is under MIL-A-8625 and it assists in preventing corrosion and adhering to paint.

Besides, it has an energy efficiency that is higher than that of chromic acid.

Type II Anodizing

This is also known as regular anodizing and it is the most popular version of anodizing aluminum tubes.

Besides, Type II anodizing is widely used with a sulfuric acid solution, leading to the formation of a thicker coat than average.

Also, it offers a hard finish than that of chromic anodizing with a thickness ranging between 0.0002 and 0.001 inches.

Type II anodizing forms porous surfaces that remain conducive to surface finishes that entail coloring.

This allows you to color the anodised aluminum tube with various colors such as gold, red, blue, black, etc.

Before conducting Type II anodizing, you can treat the aluminum tubes to give them a matte appearance.

When you dye anodized aluminum tubes, the color will stay for longer periods especially when you seal them properly.

Besides, using sulfuric acid is cost-effective and offers many variations when it comes to anodizing aluminum tubes, and in several colors.

Also, the waste treatment is simple to control and monitor than chromic acid anodizing.

Type II Anodizing Aluminum Tube

Type III Anodizing

This type of anodizing is also known as hard anodizing, and will also use sulfuric acid in the anodization process.

Also, it will provide the thickest anodized layer that is more than 0.001 inches.

Besides, Type III anodizing offers the highest abrasion resistance and you can also dye it in various colors.

However, this type of anodizing is not suitable for aluminum tubes that have very tight tolerances.

Also, you can apply it to improve electrical insulation.

Other Anodizing Types

Phosphoric Acid

This anodizing process enhances the performance of anodized aluminum tubes in high-humidity environments.

Boeing Process is also another name for this anodizing process since it finds its application in aircraft industries.

Architectural Anodizing

This anodizing process is suitable for industries that value durability and appearance.

For instance, you will anodize the aluminum tubes if you plan to use in to permanently supporting external parts of a building.

Tubes Made From Architectural Anodizing

Bright Dip Anodizing

This process entails using nitric acid and phosphoric acid to achieve a shiny, reflective look.

Bright dipping anodizing is suitable for 5000 and 6000 series of aluminum alloys.

A harder aluminum oxide layer means it will be brighter.

Bright Dip Anodized Aluminum Tube

What Are The Advantages Of Anodized Aluminum Tubes?

These include the following:

Various Resistance

Anodized aluminum tubes have a myriad of resistance features such as:

- Abrasion resistance

- Corrosion resistance

- Erosion resistance

- Fade resistance

- Graffiti resistance

Pleasing Appearance

Anodized aluminum tubing will stand out during application since they can come with a natural or tinted look.

Low Cost

The finishing cost and maintenance level are low, hence giving the anodised aluminum tubes better value over time.

Stable Color

Anodic dyes will stick on the porous surface of anodized aluminum tubings, hence increasing their stability.

This allows it to maintain the color even if you expose it to UV rays.

For this reason, the anodized aluminum tube will not chip, peel, or flake, making them maintain its appearance for several years.

Easy Maintenance

It is simple to maintain the surface of anodized aluminum tubes since you can use a mild detergent to clean them.

Electrical Insulation

The oxide layer that forms following anodization makes it behave like an insulator.

Environmentally Safe

It is possible to use recycled aluminum metals to make anodised aluminum tubes.

Besides, you can resurface anodized aluminum tubes when the need arises.

Increased Lifespan

The life expectancy of anodized aluminum tubing depends on the thickness of the oxide layer.

This means that if you have a thicker layer, the anodized aluminum tube will last for several years.

For instance, anodised aluminum tubes can last between 20 and 30 years.

Prime Base

You can use anodized aluminum tubes as a base when you need to apply paint.

Various Sizes

There is a broad range of aluminum tubes that you can anodize, meaning you can apply it in different applications depending on the needs.

Strength

Anodised aluminum tubes are harder than pure and natural aluminum tubes.

Lubrication

Anodized aluminum tubes feature better lubrication than standard aluminum tubes.

The anodization process forms pores on the surface enabling it to retain film or lubricants.

Dyeing

It is possible to dye anodized aluminum tubing since the standard version will not support dyeing.

This allows you to achieve various colors or color combinations.

Increased Adhesion

Anodised aluminum tubes will greatly adhere to primers and adhesives since the oxide layer contains deeper pores.

Pores are holes those adhesives and primers will fill hence form strong adhesion.

Anodized Aluminum Tubes Are Strong, Resistant, Appealing To The Eye Among Other Numerous Benefits

Are There Disadvantages Of Using Anodized Aluminum Tubes?

Anodised aluminum tubes will not offer suitable resistance to chemical damages.

When you expose the anodized aluminum tubing to corrosive substances for long periods, the surface will break down.

This issue is common in areas with high chemical emissions due to acidic chemicals.

How Do You Anodize Aluminum Tubing?

Anodizing process may appear tasking but it is straightforward.

Here are the steps you will follow when planning to make anodized aluminum tubing:

Step 1

This stage entails cleaning the aluminum tubes before you begin the anodizing process.

It is important to eliminate all forms of contaminants and impurities as it will hinder the anodization process.

Step 2

Here, you will place the aluminum tube in a bath containing an electrolytic liquid solution, then apply a direct electric current.

This will form positive electric charges within the aluminum tubes and negative charges within the plates of the electrolyte liquid solution.

An electrochemical reaction will begin and the surface of the anodised aluminum tubes will have pores.

This will allow the aluminum tube to bind with oxygen ions in the solution containing negative charges.

The reaction leads to the formation of an aluminum oxide layer that is highly durable and resistant than pure aluminum.

Diagrammatic Illustration Of The Anodizing Process

What Color Options Are Available For Anodized Aluminum Tubes?

There are various color options that you can use on anodized aluminum tubes.

This is because anodizing processes have a wide array of color options.

Examples of anodizing colors options include the following:

- Clear

- Bronze

- Black

- Champagne

- Pink

- Blue

- Brown

- Red

- Yellow

- Violet

- Green

- Grey

What Are Some Design Tips For Anodized Aluminum Tubing?

Here are some tips that will assist you in smoothening the anodization process or anodized aluminum tubes:

Monitor The Tolerances

It is important to understand that the anodizing process will add some extra thickness to the aluminum tubes.

This is because it can affect tolerances.

When the tolerance level is tight, you can use Type II or Type I anodizing on the aluminum tubes since the oxide layer is not that thick.

Besides, during the design phase, you can take into consideration the additional layer.

Corners And Edges

When anodizing aluminum tubing, ensure the radii of the corners and edges is at least 0.5 millimeters.

This will allow you to prevent it from overheating when the electrical current is at a high concentration.

Consider Alternative Finishing Stages

Anodizing aluminum tubes is an electrochemical method meaning its effect is not similar to that of polishing or blasting.

For instance, machining aluminum tubes may result in the machine leaving scratches on the final surface.

This means for you to achieve a uniform finish, you can use methods such as:

- Bead blasting

- Polishing

- Mechanical finishing

Operate With Batches

When coloring anodised aluminum tubes, it is suitable to work with small batches.

This allows for a higher level of color uniformity since it is hard to match colors from various batches.

What Are The Applications Of Anodized Aluminum Tubes?

Anodizing is a cost-effective and quality method of applying a surface finish to aluminum tubes.

This makes it a popular selection for numerous industries.

Several industries use anodized aluminum tubing, and they include:

- Aerospace industries

- Consumer goods

- Architectural industries

- Automotive industries

- Homeware sections

Anodized Aluminum Tubes Are Suitable For Architectural Use

How Do You Check Quality Of Anodized Aluminum Tube?

There are several ways to know if the aluminum tube has undergone a successful anodizing process.

Here are some methods you can use to check for quality:

Inspect The Matter finish

Here, you can know what the matte finish is due to the anodizing process.

Perform An Easy Scratch Test

Here, you can use a coin to scrape the surface of the anodised aluminum tube.

If the scrape produces a visible scratch, the aluminum is polished and not anodized.

An anodized aluminum tube is scratch-resistant.

Color Dispersal

A successful anodizing process will lead to a uniform surface and the color dispersal of the anodized aluminum tubes will be even.

Some of the anodizing flaws to inspect on the final anodised aluminum tube include:

- Anodizing burns that occur due to high current densities

- Inadequate agitation within the anodizing process

How Much Does Anodizing Aluminum Tubes Cost?

One reason why using anodizing processes is common is due to their cost-effective nature.

However, the cost of anodizing aluminum tubing depends on various factors.

These factors include dimension, anodizing type, quantity, shape, and color.

For instance, dying complex anodized aluminum tubes cost more than simple tubes requiring no color finish.

Why Do Anodised Aluminum Tubes Have A Metallic Sheen To Them?

Metallic Sheen In Aluminum Tube

After the coloring process, anodized aluminum tubing will display a metallic appearance.

Two factors cause the anodized aluminum tubes to have this look.

The first reason is because of a uniform electrochemical etching which causes the surface to be rough.

Anodised aluminum tubes will have a rougher surface if the pores are deeper, and the colors will become durable due to this effect.

The second reason is that light that hits the surface of the anodized aluminum tube will interrelate with colorants.

Also, it will partly interact with the top metal layer that has no color.

This will cause the light that reflects to your eye to contain a combination of two light wavelengths.

The two wavelengths are because the light is reflecting from two various surfaces causing the anodised aluminum tube to shine.

Can You Refurbish Anodized Aluminum Tubing?

It is worth considering refurbishing anodized aluminum tubing that have undergone wear-and-tear or even accidental damage.

Besides, you can protect the open patches through these two processes:

- Chromate conversion coating

- RoHS compliant substitutes

When you need to restore the coating for it to have the perfect cosmetic finish, you can re-anodize the anodized aluminum tube.

Since the process entails an electrical contact for the anodizing process, it is vital to eliminate any preexisting coat.

For instance, you can use chemical or mechanical processes to remove paint that is on the anodized coat.

An etchant can be used to eliminate anodizing, resulting in a dull finish on the re-anodized aluminum tube.

To avoid this effect, you can re-polish the surface after eliminating the coat and before anodizing the aluminum tube again.

Besides, you can use a mechanical finish to remove imperfections, scratches, or pits on the anodised aluminum tube since they will remain visible.

For instance, the presence of pits will accelerate corrosion after the re-anodizing process.

Also, an anodized aluminum tube that has begun the corrosion process cannot undergo restoration that regenerates its original corrosion resistance.

However, this is possible if you eliminate a huge amount of material from its surface.

The bare aluminum metal areas will react differently when you strip the anodizing.

Therefore, it is suitable to first eliminate the coat then proceed to buff out the scratches and dents.

Since an anodized coat will form on both the inside and outside part of the aluminum tube, removing and re-anodizing will cause the dimensions to change.

This change can be in terms of a fraction of microns meaning you need to consider this change in situations where the tolerance is tight.

Also, depending on the shape, you can mask the locations with a tight tolerance before you begin to strip and re-anodize other surfaces.

How Do Anodised Aluminum Tubes And Non-Anodized Aluminum Tubes Compare?

An anodized aluminum tube has an oxide layer on its surface while a non-anodized aluminum tube has no oxide layer.

Besides, anodized aluminum tubing have several benefits over non-anodised aluminum tubes.

For instance, the anodised aluminum tube will offer a high level of resistance against corrosion from other environmental elements.

On the other hand, the non-anodized aluminum tubing is susceptible to rust when you expose it to environmental elements.

This is because they lack an oxide layer that forms a protective barrier that inhibits corrosion.

Also, you can dye the surface of anodized aluminum tubing which is not possible with non-anodized aluminum tubes.

You can add the dye within the acid bath to expose the anodized aluminum tubing to various colors.

What Shapes Can Anodized Aluminum Tubes Come In?

There are various shapes that anodised aluminum tubes come in, and they include the following:

- Square

- Oval

- Rectangle

- Round

With these shapes, you can use the anodized aluminum tubing in:

- Oil tubes

- Cylinder tubes

- Microchannel tubes

- Telescopic tubes

- Airfoil tubes

- Pump tubes

- Capillary tubes

- Customizable tubes

- Thin wall tubes, etc.

Microchannel Tubes

Are There Necessary Precautions To Consider When Anodizing Aluminum Tube?

Some guidelines worth considering when preparing aluminum tubes for anodizing include:

- Ensure the aluminum tube is consistent by working with a single metal source

- Avoid mixing aluminum alloys as they will not produce a uniform outcome

- Conduct forming and bending before anodizing as it may lead to the formation of film crazing

- Store in a dry and monitored environment away from humid areas

- Avoid using adhesives as they can leave residues that may be difficult to eliminate in the anodizing process

- Come to terms with the expectations and specifications of the anodizing process

- Watch for any welds as they may show a color difference

- Avoid anodizing aluminum tubes that have flaws such as scratches or heavy die lines

At Wellste, we have flexible MOQ, guarantee competitive prices and support OEM anodized aluminum tubing business.

So for any inquiries or questions on anodized aluminum tube, contact us now.